Do you know the different types of slip rings? If not, don’t worry. You’re not alone. Even those within the industry need help to differentiate between all the types.

This guide will assist you in making sense of it all. We’ll start by explaining a slip ring and how it types. Then, we’ll introduce you to the different types of slip rings and discuss their benefits and drawbacks.

We hope this guide provides you with all the information you need to choose the right slip ring for your application.

What Are Slip Rings

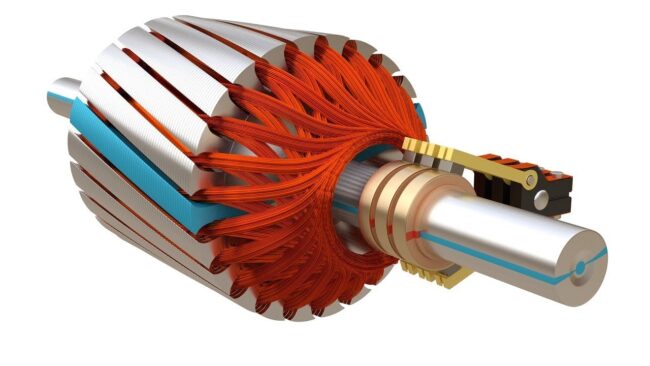

Suppose you’re not familiar with slip rings. In that case, they’re a rotating electrical connector that allows current and signals to pass between a stationary and rotating component. They’re often used in machinery and equipment where wires or cables are impractical or impossible.

There are a few different types of slip rings, each with unique benefits and drawbacks. This article will look at the three most common types: the brushless ring, the contact ring, and the carbon brush ring.

Different Types of Slip Rings

There are three types of slip rings: mechanical, hydraulic, and electrical.

Mechanical slip rings are the simplest type and rely on metal-on-metal contact to create a circuit. They’re generally less expensive than hydraulic or electrical slip rings but have shorter lifespans and are less efficient.

Hydraulic slip rings use a small amount of oil to create a circuit. They’re generally more reliable and efficient than mechanical slip rings. However, they also tend to be more expensive.

Electrical slip rings are the most common type, and they use a rotating electrical contact to create a circuit. They offer the best performance and lifespan of the three types of slip rings.

– Mercury Contact Slip Rings

Another type of slip ring is the mercury contact slip ring. This type is more complex than others and works by using contact points separated by a thin layer of mercury. The mercury allows for smooth, continuous operation while creating a remote connection between the two components.

The advantages of this type of slip ring are that they have a higher current carrying capacity than other types and can transmit higher frequencies, up to 400Hz in some cases. It’s also resistant to dust and corrosion, which makes it great for applications where these factors could be an issue.

However, there are downsides to this type of slip ring as well. These include the fact that it requires more maintenance since the mercury needs to be replaced now and then, as well as its relatively high cost compared to other types. It’s also important to note that using mercury contact slip rings can pose a health hazard if not handled properly.

– Through Hole Slip Rings

Through-hole slip rings are the most common type of slip ring. Using a hollow center, they allow electric wires to run through its center, making it perfect for applications that transmit data or electric signals.

These slip rings are also known as “hollow shaft” or “multi-conductor”. They can be used in many sectors, such as medical, security systems, robotics, automated machinery, etc.

The advantage of through-hole slip rings is that they are easy to install and accommodate larger cables that must pass through the middle of the device. They also have a wider variety of mounting options due to their extended design, which helps find the best placement for your motors or pumps.

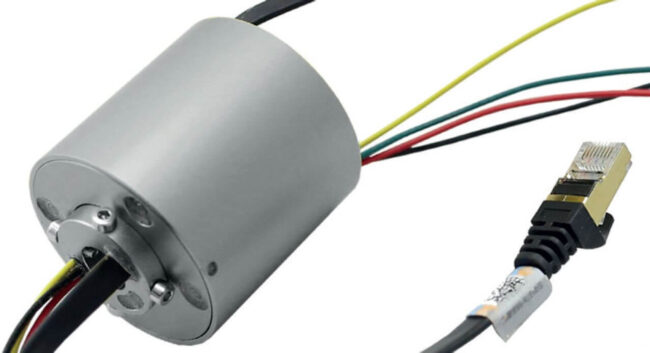

– Ethernet Slip Rings

If you’re looking for something more advanced than a standard slip ring, then an Ethernet slip ring might be the answer. As the name implies, these rings are designed to transmit high-speed data signals on Ethernet networks.

The transmitted data is done so in a secure and reliable manner and can speed up to 10Gbps. It makes it ideal for applications that require large amounts of data to be transferred quickly, such as telecommunication systems or broadcasting equipment.

These slip rings are often used in motion control systems that can help automate complex processes by allowing computers and other devices to communicate wirelessly. In addition, they provide uninterrupted rotation, which enables them to be used in rotating machines like cameras or antennae without any interruption in service.

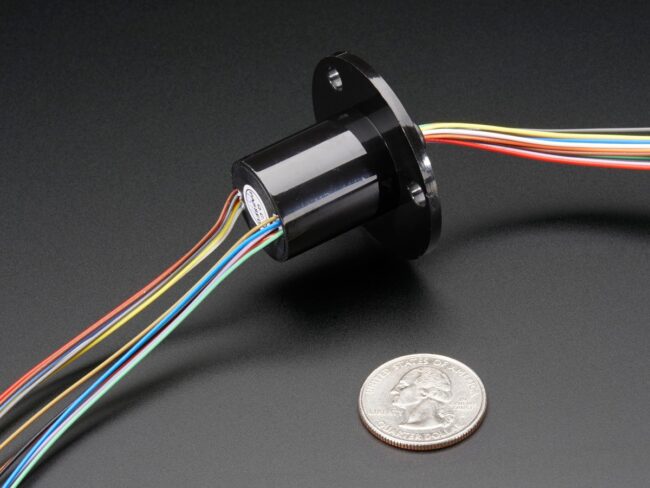

– Miniature Slip Rings

Are you looking for a slip ring that’s small and super lightweight? Then the miniature slip ring is the one for you. These are great for connecting electrical cables and other components in tight spaces with limited access.

The miniature slip ring is designed to rotate smoothly with minimal drag, typically up to 500 rpm, but it depends on the model. It’s also incredibly durable because it’s made of stainless steel, brass, aluminum alloy, and sometimes unique materials.

Thanks to its compact size and weight, the miniature slip ring is commonly used in medical equipment, machine tools, robots, and many other applications where size and weight are important factors.

– Fiber Optic Slip Rings

The next type of slip ring is the fiber optic slip ring. As the name implies, this slip ring uses fiber optic technology to link rotating and stationary components together. It’s the most advanced type of slip ring, and it’s often used in compassionate applications where electrical signals aren’t suitable.

Fiber optic rings are easier to install and maintain than electrical slip rings. They feature low signal loss without amplification and have a higher data rate than electrical slip ring. However, they tend to be more expensive than their counterparts and may require additional shielding.

– Wireless Slip Rings

The last type of slip ring we’ll cover is the wireless slip ring. As you might have guessed, this slip ring doesn’t use any wires or cables, making it an excellent option for applications where lines are impractical or hazardous.

Instead, this slip ring uses a combination of electromagnets and Hall effect sensors to transmit data and power wirelessly via radio frequency signals. It makes these rings highly efficient and reliable, with fast data transmission rates and the ability to handle large amounts of data in a short period.

Something else to keep in mind about wireless slip rings is that they can be used in hazardous areas where cabling can be dangerous, such as in extreme heat or cold environments, high-altitude locations, and deep underwater. Remember that these can be expensive compared with other types of slip rings.

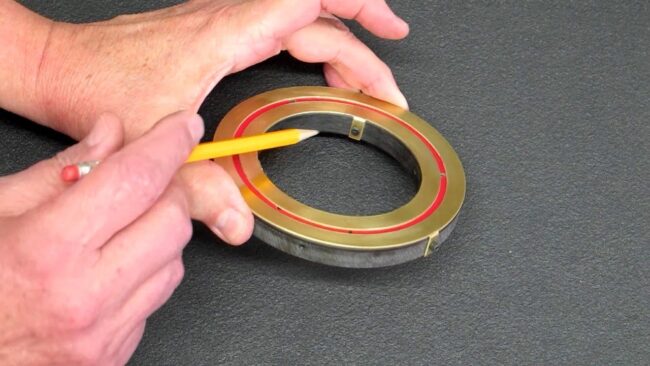

– Pancake Slip Rings

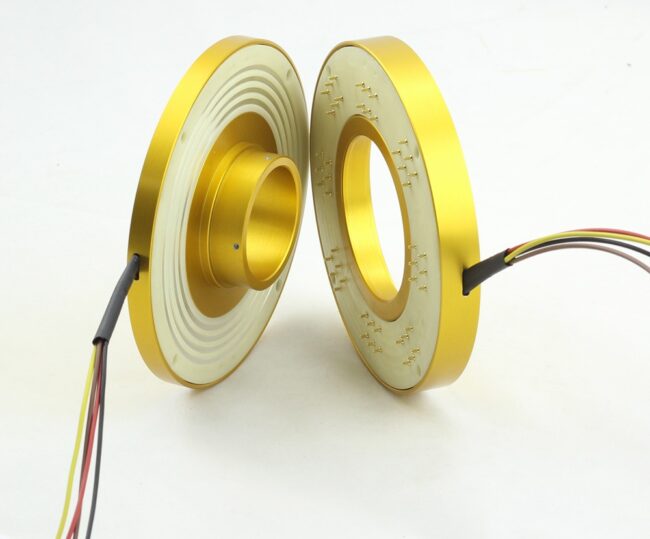

The pancake slip ring is a rotating electrical connector that is flat and circular. It gets its name from its resemblance to a pancake, with its thin profile and wide diameter.

Pancake slip rings are often used in high-speed or high-voltage applications, as they can handle high current loads without overheating. They are also available in various contact configurations so that you can find the perfect one for your specific application.

Applications of Different Types of Slip Rings

With so many different slip rings, you may wonder what they’re used for. Slip rings are used in various applications, from simple home appliances to advanced machinery and robotics.

Slip rings are commonly used in medical equipment to transfer electricity and data signals between moving and rotating components. They’re also used in military equipment, such as weapons and communications systems.

In industrial applications, slip rings are often found in motors and conveyor systems. They’re also used to transfer power to moving parts on automated assembly lines and production lines.

In the entertainment industry, slip rings are often used in lighting and audio/video systems. They allow the lights or sound system to stay connected while the components rotate around a central point.

Ultimately, slip rings serve an essential purpose by allowing components to stay connected while moving or rotating. With so many different products available on the market today, it’s more important than ever that you choose the right one for your needs.

Benefits of Using Different Types of Slip Rings

You’ve probably heard of slip rings before, but you may not realize how many are available. From brushless slip rings to pneumatic slip rings and even composite slip rings, there are various options for this crucial piece of machinery. So why use different types?

Each type has its benefits, depending on the type of application you need. Brushless slip rings offer reduced wear and tear, improved signal quality, and increased electrical safety. Pneumatic slip rings provide increased mobility and are ideal for applications that need to be frequently rotated or moved. And finally, composite slip rings have a lightweight design and protection from electrical noise.

No matter what application or industry you’re in, there’s sure to be a slip-ring that can help you get the job done better!

Conclusion

So there you have it: a comprehensive guide to the different types of slip rings. Hopefully, this article has helped you better understand the function and purpose of every slip ring and armed you with the knowledge you need to make the right purchase for your specific needs. Thanks for reading!