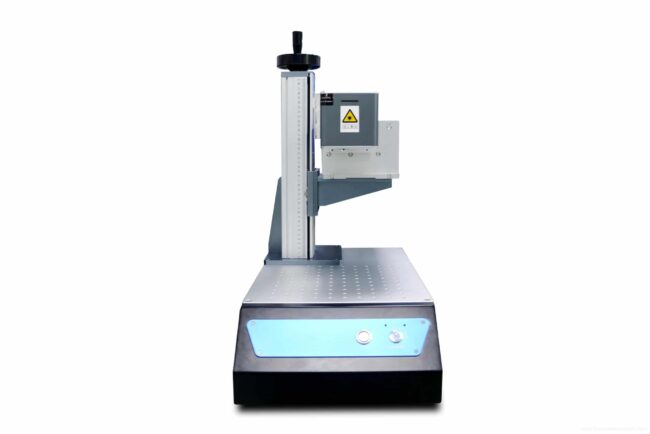

UV laser marking machines are used very often as they are an ideal choice if you work with plastics, ceramics, glass and many other materials. Compared to fiber laser engraving machines that are primarily for metal, UV laser engraving machines are used more for the materials we mentioned. The popularity of these devices is great primarily because it has significantly improved precision and simplified use when compared to machines from several decades ago.

They are very durable and can work for a very long time, so they are a cost-effective choice. Of course, they must be regularly and properly maintained in order to last as long as manufacturer intended. Precisely because they will often work, and you have paid a lot of them, you must not be careless when it comes to maintenance, otherwise investment will not pay off, because this not so cheap machine. Read more about UV laser marking machine and tips for maintenance below.

About UV laser marking machine

It is a device that uses ultraviolet rays to change the surface of the material you are working with. It is mainly used for engraving, which is why it is also called UV engraving. There are lasers of different strengths, it is chosen according to which material you mostly work with. See this for more info about uv laser marking machine output power. They are the most popular choice because they work very fast, they are durable, and also maintenance is cheaper when compared to other devices which is very important. Only it is not suitable for metal, fiber machines are used more for that purpose, and for everything else the UV engraver is the right choice.

How do they work?

To know how to properly maintain them, you also need to know how they work. If you’ve heard of photo etching effects, you’ll find it easier to understand how this device works. UV photons during contact with the surface refract molecules and the so-called cold treatment occurs. That is why the material remains smooth. It is a very precise machine and easy to focus on. Colors spectrum varies considerably.

How to use it?

We can say that proper use is the first step to make these machines work as long and efficiently as possible. Therefore, we will explain to you basics of how to use them, before we move on to the maintenance instructions. The first thing you should always check before it starts is whether the set up is right. And to check if there is something that will interfere with the work. Then you need to know well the software you are using to give instructions to the machine. There are a few software that are the most popular, so it would be good to know at least two. Also check whether drivers are up to date. Then check the control unit that is directly responsible for the operation of the shooting unit that fulfills the primary function of this machine. Lastly, it is important that you wear protective equipment because the UV laser is dangerous to human health, especially the eyes.

Tips for maintaining

1. Regular cleaning of the lens

Some of the things you have to do every day and some occasionally. Cleaning the lens is one of the tasks you need to do every morning before putting the machine into operation. Of course, turn off the device first, and only then start cleaning. If it is turned on, you are exposing yourself to the potential danger. There are usually a few mirrors, so you need to clean everything separately. On the manual you will find all the necessary information where each one is located so not to miss any of them. You have to be very careful while doing this, because although lenses are not too fragile, it is certainly possible to damage them if you are not careful.

It is usually the case that you can clean several mirrors without removing them from the machine, but there will be some that will need to be removed in order to be properly cleaned. So be especially careful with the lens you remove, as it is possible that you will damage it even more easily.

2. Periodic cooling check

In order for the UV laser marking machine to work for as long as possible, it is necessary to ensure that the cooling is always good, otherwise it will overheat and this will damage the device. While fiber laser marking engravers cool only by using air because that is enough for them, when it comes to UV engravers, they also need water cooling. That is why it is necessary to check the water tank once a month, clean it and replace the water. It would be best to use distilled water, to avoid limescale and other things that can be found in tap water. Also leave enough space around the machine for air cooling to work. Device should not exceed a temperature of 30 degrees Celsius, because anything over that temperature that can damage it. If it exceed this temperature, switch off the machine immediately and wait for it to cool down, then check the cause of the overheating. Of course, when you change the water and clean the pump, everything must be disconnected from the power source.

3. Don’t forget the air pump

Although water is primarily used for cooling, air is also important. So don’t forget to clean the air pump from time to time, because they can get dirty, primarily due to dust. If you hear that your machine is too loud, it is definitely time to clean the air pump. But you shouldn’t wait for that sign, but do it regularly. It is best to vacuum it every week or two.

4. Check sliding track

In order for your cuts to be accurate and for the lasers to be stable, it is necessary to periodically check the sliding track. When we say occasional, we mean every few days. Wipe first with a cotton cloth and then apply engine oil to make everything run smoothly.

Conclusion:

When you have already invested significant funds in the purchase of a UV laser marking machine, it would be foolish to neglect maintenance and thus significantly shorten its service life, which is otherwise very long when properly maintained.